As a professional in the packaging and materials industry, I understand the importance of selecting the right material for your specific needs. One material that stands out in numerous applications is laminated aluminum foil with kraft paper. This versatile product offers exceptional benefits, from superior protection to cost-effective performance. In this article, I’ll address the most common questions I get from customers regarding laminated aluminum foil with kraft paper, focusing on its structure, benefits, applications, and more.

What is Laminated Aluminum Foil with Kraft Paper?

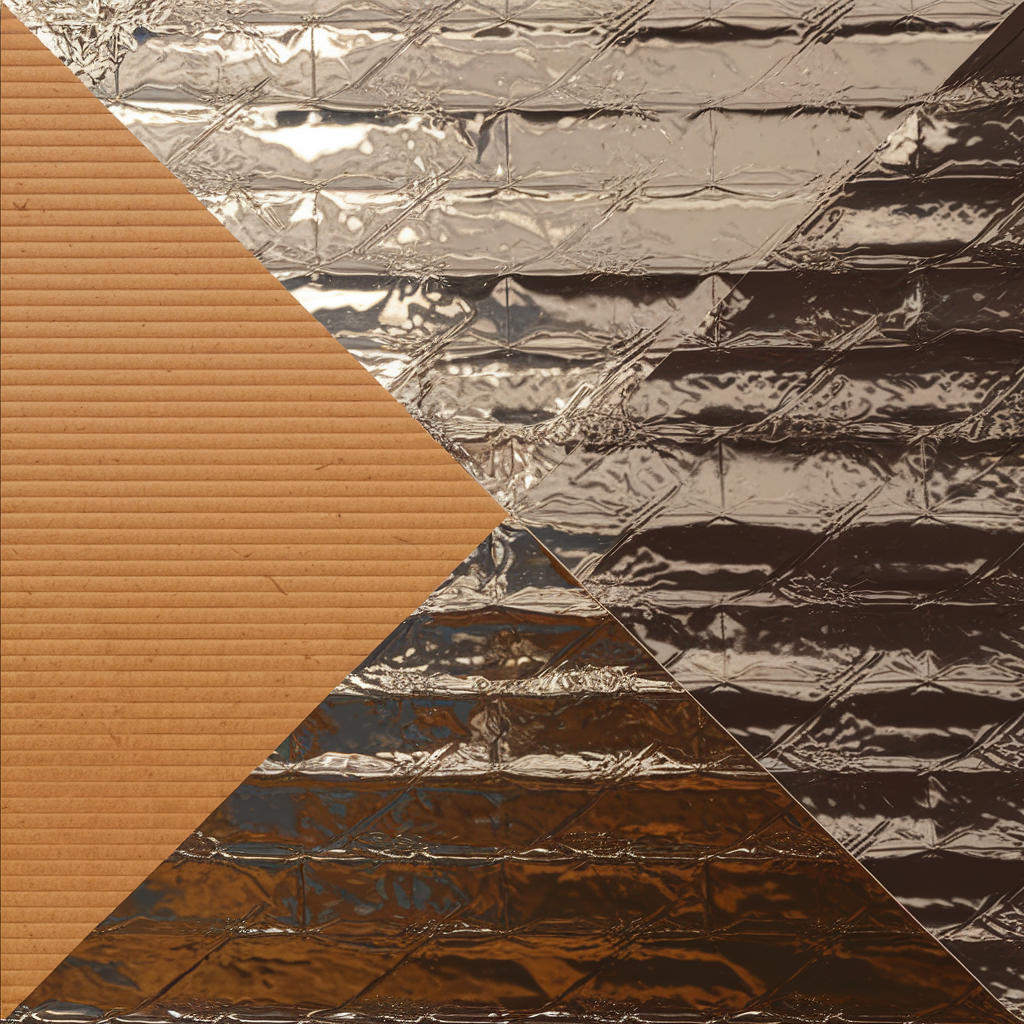

Laminated aluminum foil with kraft paper is a composite material that combines the lightweight yet sturdy properties of kraft paper with the barrier and protective qualities of aluminum foil. This material is produced by laminating a layer of aluminum foil onto kraft paper, creating a multi-layered structure that offers unique benefits in various industries, particularly in packaging.

Structure:

- Kraft Paper: Kraft paper is a durable, natural paper made from wood pulp. It is known for its strength, tear resistance, and eco-friendly nature.

- Aluminum Foil: The aluminum layer provides an excellent barrier against moisture, light, air, and gases, making it ideal for preserving the contents inside the package.

This combination allows for the strength of kraft paper, combined with the protective features of aluminum foil. It is often used in packaging materials, especially for products that require long shelf life or protection from external environmental factors.

Why Choose Laminated Aluminum Foil with Kraft Paper?

1. What are the benefits of laminated aluminum foil with kraft paper?

The unique combination of kraft paper and aluminum foil creates a material that offers several key advantages:

- Excellent Barrier Properties: The aluminum foil provides a robust barrier to moisture, light, oxygen, and other gases, ensuring the preservation of the product inside. Whether you’re packaging food, pharmaceuticals, or other sensitive materials, the barrier properties help extend shelf life and maintain product quality.

- Durability and Strength: Kraft paper offers natural strength and tear resistance. It’s also relatively thick and rigid, giving the material more structural integrity. This makes it a great choice for products that need both protection and support.

- Eco-friendly: Kraft paper is biodegradable and recyclable, making it a more environmentally friendly option compared to many synthetic packaging materials. This feature appeals to companies that prioritize sustainability in their operations.

- Cost-Effective: Laminated aluminum foil with kraft paper can be a cost-effective alternative to other barrier materials, especially for industries that need to balance performance with budget constraints.

2. How does laminated aluminum foil with kraft paper improve product preservation?

The aluminum foil layer serves as an outstanding moisture and light barrier, two of the most common factors that degrade many types of products. For food products, for example, this layer prevents oxidation, preserves flavor, and protects against contamination from outside elements. Similarly, in the pharmaceutical industry, it helps keep active ingredients stable and protects them from environmental factors that could reduce their efficacy.

The kraft paper adds an extra layer of mechanical protection, making it harder for external forces to compromise the package’s integrity. This is especially important for sensitive or fragile products that might be damaged during transportation or storage.

3. Can laminated aluminum foil with Kraft paper be used in food packaging?

Yes, absolutely! One of the primary applications of laminated aluminum foil with kraft paper is in food packaging. The combination of aluminum’s excellent moisture and light barrier properties with the strength of kraft paper ensures that food items stay fresh longer and are well protected from external contamination. Common food products that use this material include:

- Snacks and dried foods

- Coffee and tea packaging

- Confectionery items

- Frozen foods

By keeping moisture, air, and light out, the material helps preserve the flavor, texture, and nutritional value of food products. Additionally, it provides a strong outer layer that can withstand the rigors of transportation and storage.

4. How is laminated aluminum foil with kraft paper used in pharmaceuticals?

Laminated aluminum foil with kraft paper is also widely used in the pharmaceutical industry. Many pharmaceutical products require excellent barrier protection to maintain their efficacy and shelf life. In this industry, the material is used to package tablets, capsules, powders, and even some liquids. The aluminum foil protects the product from moisture and air, while the kraft paper provides extra mechanical protection and durability, which is essential during transport.

In blister packs, sachets, and pouches, the laminated structure ensures that the medication remains uncontaminated and stable. This is critical in ensuring that drugs maintain their potency and effectiveness for as long as possible.

5. Is laminated aluminum foil with kraft paper used in non-food industries?

Yes, laminated aluminum foil with kraft paper is also used in various non-food sectors. It’s a highly versatile material that can be tailored for different applications, including:

- Cosmetics and personal care products: The barrier properties help preserve the shelf life and integrity of items like lotions, creams, and perfumes.

- Industrial packaging: This material is often used for packaging chemicals, electronics, and even construction materials, where moisture and air need to be kept out.

- Medical and health-related products: As mentioned earlier, this material is ideal for pharmaceutical packaging, but it can also be used for other health-related items like medical devices or supplies.

6. How is laminated aluminum foil with kraft paper manufactured?

The manufacturing process of laminated aluminum foil with kraft paper involves several key steps:

- Coating: First, the kraft paper is coated with a layer of aluminum foil. This can be done using several methods, such as extrusion coating or lamination, depending on the desired thickness and strength of the finished material.

- Lamination: In this process, the aluminum foil is bonded to the kraft paper using heat and pressure to form a solid, unified composite material. The strength of the bond between the layers is critical to the performance of the final product.

- Finishing: After lamination, the composite material is typically rolled into sheets or converted into specific packaging formats like pouches, bags, or roll stock, depending on its end use.

7. What industries use laminated aluminum foil with kraft paper?

Laminated aluminum foil with kraft paper is utilized across various industries due to its versatility. Some of the key sectors include:

- Food and beverage industry

- Pharmaceutical and healthcare sector

- Cosmetics and personal care

- Automotive and electronics

- Industrial packaging

The combination of its barrier properties, strength, and eco-friendliness makes it suitable for a wide range of products in these industries.

8. Can laminated aluminum foil with kraft paper be customized?

Yes, laminated aluminum foil with kraft paper can be customized to meet the specific needs of different industries. Whether it’s adjusting the thickness of the foil, adding printing capabilities for branding, or modifying the structure for unique product requirements, this material is highly adaptable.

Customization ensures that companies get the right combination of properties—whether they need added strength, better barrier protection, or enhanced aesthetics. Many manufacturers offer custom sizes, finishes, and coatings to ensure the product fits the customer’s precise needs.

Conclusion: Laminated Aluminum Foil with Kraft Paper

In conclusion, laminated aluminum foil with kraft paper is a highly functional and versatile material that provides superior protection for products across various industries. Its ability to combine the natural strength of kraft paper with the barrier properties of aluminum foil makes it an excellent choice for food packaging, pharmaceuticals, cosmetics, and more.

If you are considering using laminated aluminum foil with kraft paper for your packaging needs, it’s crucial to understand its benefits, applications, and customization options. Whether you are in the food, pharmaceutical, or industrial sector, this material offers an eco-friendly, durable, and cost-effective solution to meet your packaging requirements.

If you have any further questions or need assistance with selecting the right packaging solution, feel free to reach out to me. I’m always happy to help!